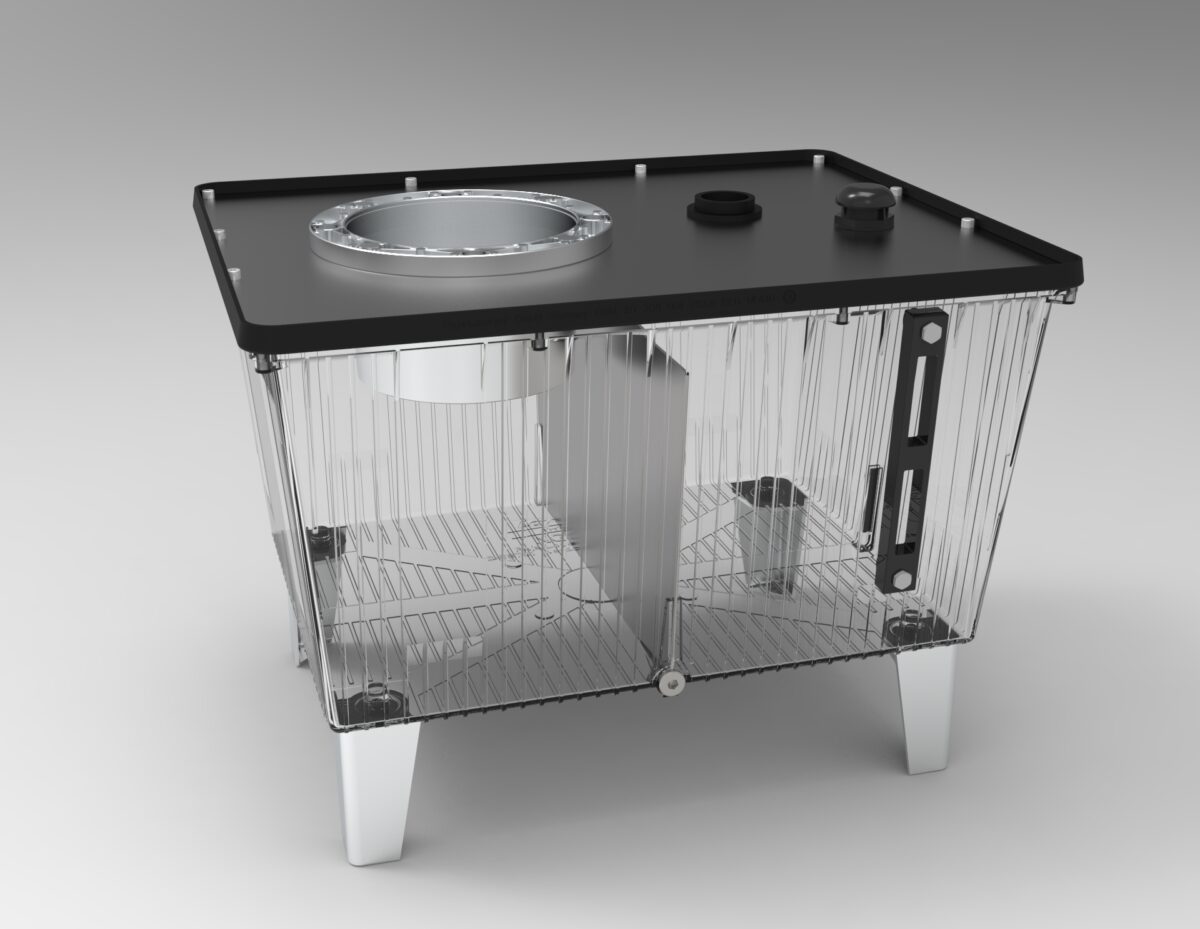

R+L Hydraulics GmbH presents hydraulic tanks of nominal size NG130 made of cast aluminum. The oil tanks are unpainted, stackable and easy to handle thanks to their low weight. They are characterized by a high cooling capacity.

The nominal size NG130 aluminum containers have a usable volume of 123 l. “This is unique in the field of aluminum tanks,” says Patrick Laupitz, who is responsible for sales in the hydraulics sector at the fluid and drive technology specialist in Werdohl in the Sauerland region. Thanks to the calculated thin-walled tank design, the NG130 has an “integrated” cooling capacity of 2.1 kW at D t = 40° C. “This means that the use of an oil cooler can be dispensed with in many applications,” says Laupitz. “Further advantages are the low weight of just 25 kg, the easy handling and the stackability of the containers. This not only saves transportation costs, but also storage space.”

In addition to the large hydraulic tanks, R+L Hydraulics offers other sizes from a usable volume of 3 liters. All tanks are optionally available with accessories such as lids, oil level indicators, cast feet, castors and filling and ventilation filters. Baffle plates are also available for the NG130.

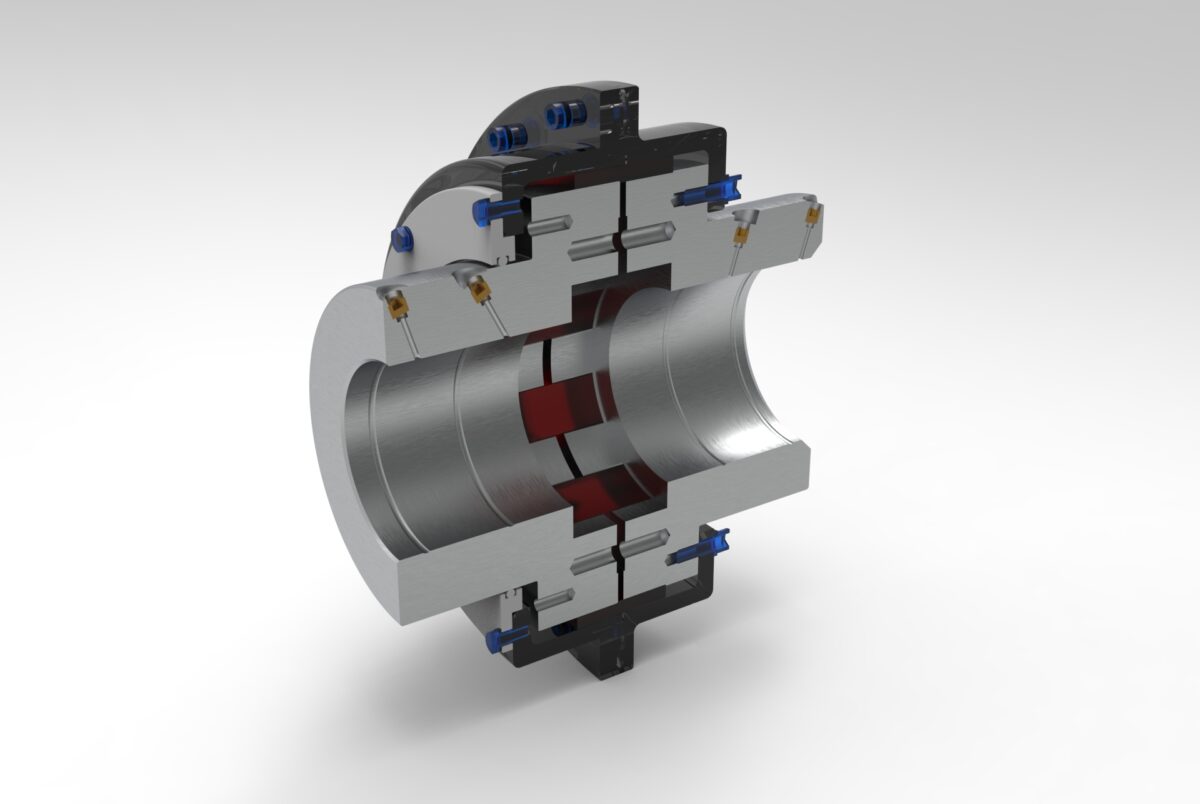

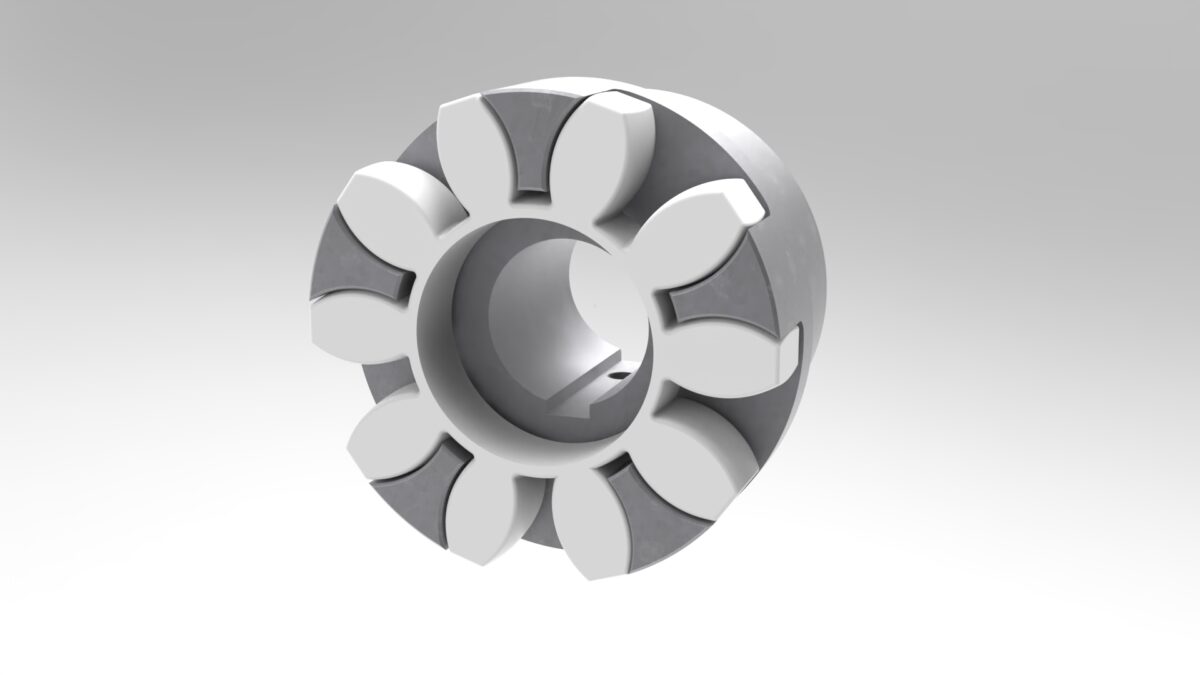

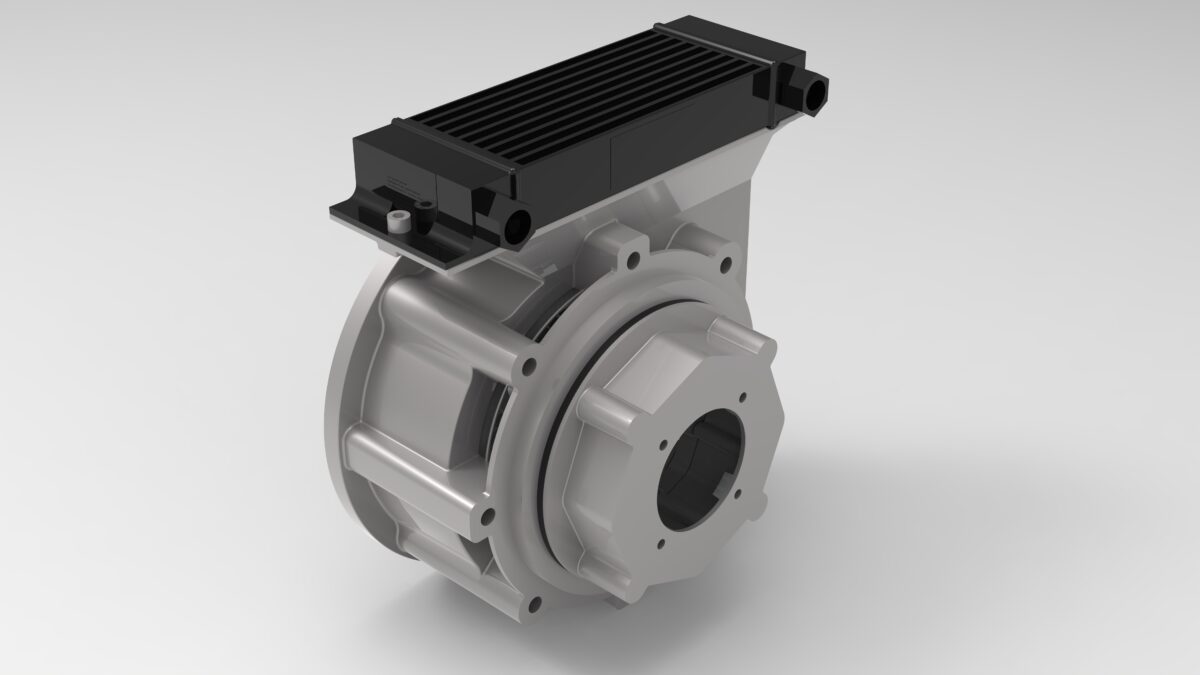

R+L Hydraulics develops, produces and sells a wide range of components for fluid and drive technology, including other hydraulic accessories and industrial couplings such as torsion and jaw couplings, bellhousings, damping elements, heat exchangers and coolers. The products are used in a wide variety of applications in mechanical engineering, shipbuilding and vehicle construction, energy and environmental technology, in the steel industry and offshore technology as well as in special applications in plant engineering.

Picture:

View inside the NG130 aluminum tank from R+L Hydraulics with accessories